Part 1: Strategies and the components you need

As we mentioned last month in Data Centers: The Need for Speed!, data center construction continues to grow at lightning speed. Another reality is that, as soon as the data center complete, it operates 24/7. This constant operation creates a massive amount of electricity consumption to power servers, process data, and keep the surrounding facilities running. This much electricity means, you guessed it, HEAT!

The heat must be efficiently removed from the data center, or the electrical components will malfunction, servers will exceed their specified temperature—and relative humidity—range, and the equipment will go offline. No data center manager wants to receive that alert on his/her mobile device. Fortunately, a variety of cooling strategies are available:

- Air conditioners and air handlers

Computer Room Air Conditioner (CRAC) or Computer Room Air Handler (CRAH) units are the most common solution. These blow cold air in a set pats to remove the hot air from the area. - Hot aisle/cold aisle

Cold air is distributed to the front of server racks while hot air out passes from behind the racks. This approach attempts to manage airflow to conserve energy and reduce cooling cost. - Hot aisle/cold aisle containment

This approach separates the cold and hot air in the server room and removes hot air from server cabinets. - Liquid cooling

Liquid cooling systems include air conditioners or refrigerants using cold water near the heat source. - Green cooling or free cooling

Free cooling provides a more sustainable approach to data center cooling, often involving opening a window covered with filters and louvers. The natural cooling approach saves both money and energy.

Build monitoring and maintenance into your project!

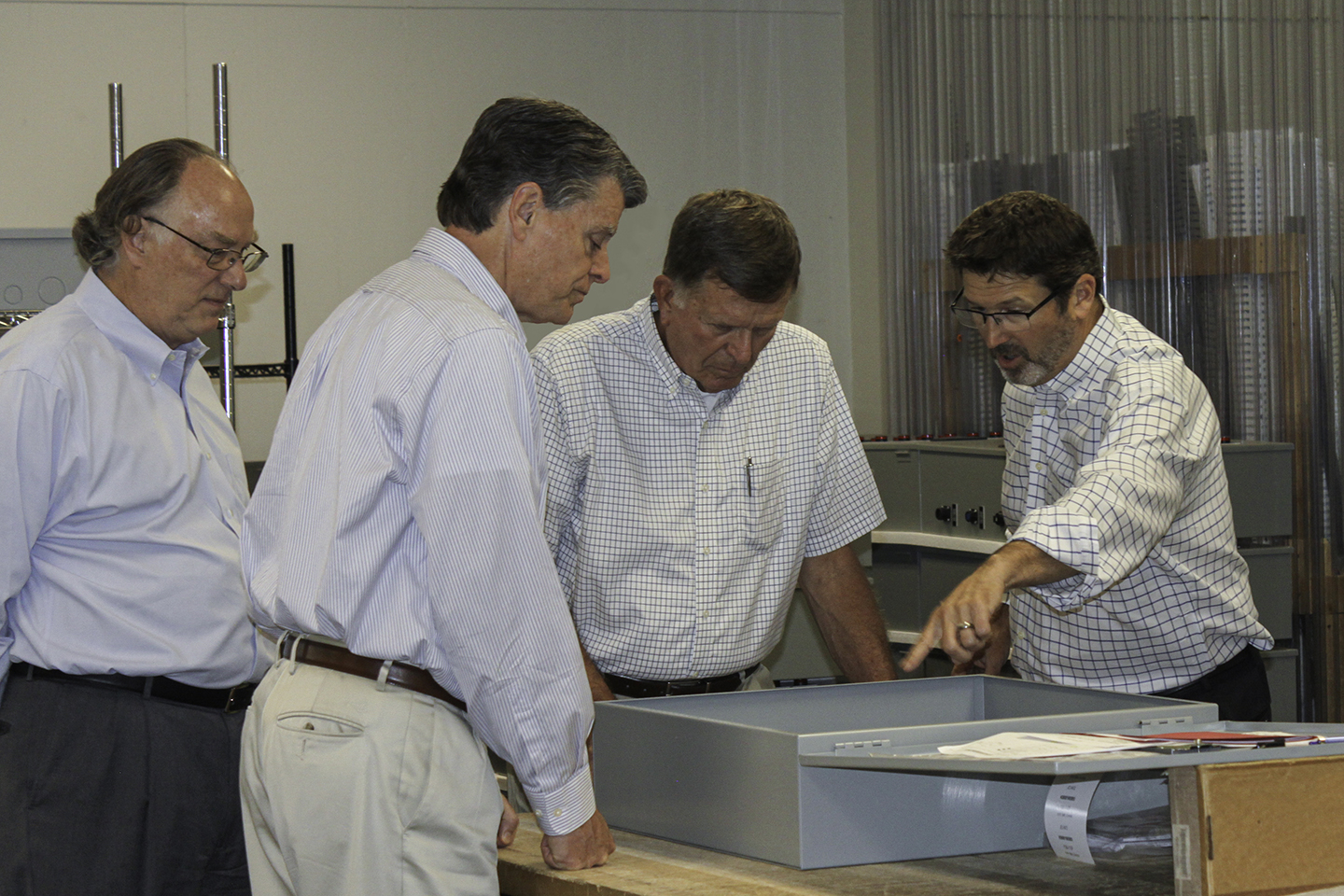

Regardless of which cooling approach you take, you must always monitor efficiency and maintain equipment. Be proactive. As you are thinking through your project on the front end, add the essential components to your BOM. These are not overly complex, but they are critical.

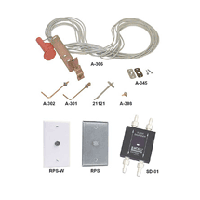

Kele offers every product you need to monitor and control temperature, humidity, and pressure, and to manage airflow. We can also provide parts to monitor compressor and chiller run time to track energy consumption. Kele’s project services and technical teams will help you think through your project on the front end and select the right components.

Ultimately, your project is successful in the long term when you avoid downtime, equipment breakdowns, and costly repairs. The right components allow you to monitor and predict when to schedule maintenance to hold the heat at bay. So select your data center cooling strategy and keep it cool with Kele!

Shop kele.com or call us for:

- Air handler components

- Actuators

- Controls

- Flow switches

- Moisture detectors

- Sensors

- …and more

Call us at 877.826.9045 or email our sales team.