Written by Gil Avery, P.E. – Reprint from September 1991 Insights

Multi-zone blow-through air handlers were popular 20 to 40 years ago when energy was cheap. Fortunately these units are not as popular today. Because they have so many negative qualities, they are prime for retrofit and offer a real opportunity to save lots of energy while improving the performance of the A.C. System.

A few of the negative features of conventional multi-zone air handlers are:

- Multi-zone air handlers use a fan that blows into a hot and cold coil plenum. As a result the fan discharge velocity pressure is lost. Multi-zone fan systems require 20 to 30% more H.P. than single-zone draw-through air handlers, with the same CFM capacity.

- The pressure drop through the coil section varies greatly with the position of the zone dampers. Consider, for example, a multi-zone air handling unit with four equal zones. Assume the drop through the cooling coil is 1″w.g. when all the dampers are in the full cooling position. The drop will only be 1/16″w.g. if only one of the four cooling dampers is wide open and the other three are in the full heat position. Almost 1″ of additional pressure is available to the cooling zone. Balancing the air flow on multi-zone units is almost impossible.

- Summer humidity conditions may be unacceptable. Raw, humid outside air is bypassed around the cooling coil when a zone is not in the full cooling position.

- The multi-zone unit is a re-heat unit. The zone thermostat is satisfied by mixing heated and cooled air and the re-heating and re-cooling are increased more than normal when the zone dampers are in a mixing mode. The air flows have increased because of the decrease in the pressure drop across the coils.

- The heating requirements of multi-zone units with an outside air economizer are high. Zones requiring heat must use mixed outside and return air at 55°F instead of return air at room temperature.

Converting a constant volume multi-zone air handler to a variable air volume unit will correct most of these issues.

The changes that have to be made to convert to VAV include:

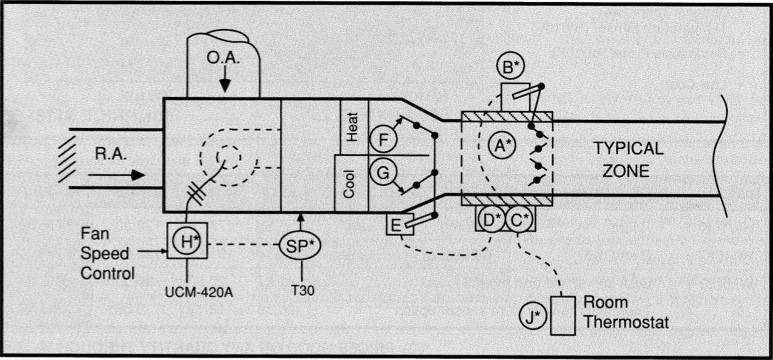

Adding a variable volume control assembly to each zone of the multi-zone unit. Each assembly consists of:

- Opposed blade zone damper (A) and zone thermostat (J) (Existing thermostat may be reused.)

- Modulating zone damper actuator (B)

- Reversing relay (C) for zone actuator (B)

- Two-position switching relay (D) for zone heating and cooling damper actuator (E)

- Adding a static pressure controller (SP) (Connect to the fan discharge plenum.)

- Adding a variable frequency drive (Control the drive speed with the static pressure controller. Many contractors just let the fan ride the curve, but the speed controller is generally a good investment, since the power varies as the cube of the flow. The savings add up fast.)

The controls will operate as follows:

- If the system is on a heating cycle (damper (F) open) and the space temperature is rising, control damper (A) will modulate closed to shut off the warm air.

- After damper (A) is fully closed, hot deck damper (F) closes completely and cold deck damper (G) opens fully.

- On a continued rise in room temperature, damper (A) modulates back open to provide cooling.

- Cycle reverses on a drop in room temperature.

- Fan speed controller (H) is modulated by the static pressure sensor (SP) to maintain the proper pressure in the fan discharge plenum.

Some of the features of this retrofit are:

- Zone air volume and heating and cooling capacity will all be enhanced. Converting to a VAV system takes full advantage of zone diversity. The air is squeezed to the zone with the largest load.

- Zone humidity conditions will be lower in the summer. All the air passes through the cooling coil and is dehumidified when the zone is on a cooling cycle.

- All mixing of heated and cooled air is eliminated, which means no more re-heat.

- Fan H.P. will be reduced from 30-50%

- Cooling load will not only be reduced by eliminating the re-heat but also by the redirection in fan H.P.

* Available from Kele

Multi-zone air handlers use a fan that blows into a hot and cold coil plenum. As a result, the fan discharge velocity pressure is lost. Multi-zone fan systems require 20 to 30% more H.P. than single-zone draw-through air handlers, with the same CFM capacity.