The most critical element that shapes a panel design project must be addressed at the very beginning of a project: where is the completed unit going to be installed? This very basic question dictates the type of protection the enclosure must provide to the equipment. The switchgear inside the enclosure must be protected from the environment, and the plant and people around it must be protected from electrical dangers.

There are three types of external threats capable of causing equipment problems:

- Solid objects, which can range from large pieces to dust

- Water, which can come with varying levels of force and multiple directions, and

- Mechanical impact.

These threats have been quantified and are described in detail in two standards: IEC 60529 (IP) covering solids and water, and IEC 62262 (IK) covering mechanical shock. Temperature is also a consideration and covered later in this series.

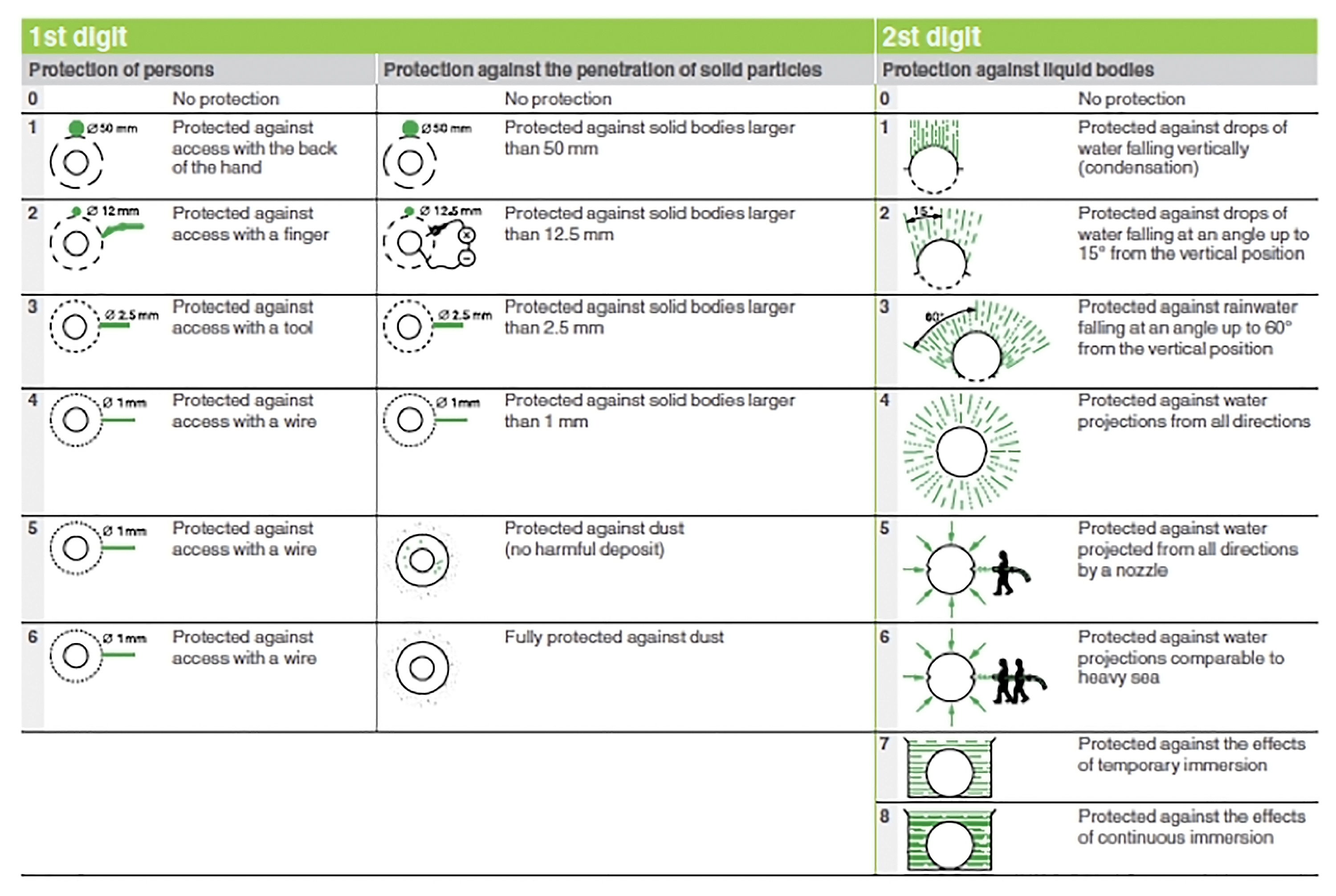

As Table 1 shows, the IP rating uses a two-digit number. The first numeral describes the degree of protection from solids and the second from the water. The higher the number, the higher the level of protection.

The IK rating is similar but has only one number between 0 and 10. Again, the higher the number, the greater the level of protection. Most industrial-grade enclosures are IK08 or better.

What level of protection is necessary?

One approach is to build every enclosure for the highest protection ratings; however, this adds a high level of complexity and cost. Customers not needing high levels of protection will not want to pay for such an enclosure. It is important to offer enough protection without going too far. In most cases, customers are very specific about their final use environment, in which case the panel builder should choose the most optimized protection level to meet the requirement. Where situations are not clearly defined, discussions with the customer will be important to answer the full range of questions.

The importance of determining the protection classifications mentioned earlier will now become clearer as it becomes a major factor in the next phase, avoiding degradation of the IP rating during installation. If we look at the installation process, the questions related to mounting the panel should be: where is it going to go, and how will it be fixed in place?

What are the mounting methods?

- Fixed to a wall—This is a common approach for small electrical distribution boards.

- Fixed to a floor—This is useful for large and heavy cabinets. Cables can enter through the top or bottom. For bottom entry, the floor can incorporate a trench or false floor, which is often simpler since it provides easier access to the bottom. Additionally, a plinth can be used to raise the panel.

- Mounted on the machinery—In some cases, the control panel is mounted directly on the machine. This approach keeps everything close together and avoids problems related to moving the machinery when the enclosure is fixed to the floor or wall. However, some machinery vibrates which can affect the enclosure over time. Where this is excessive, special provisions may be necessary.

- Movable—This situation is rare, but possible. Usually casters or a skid can be fixed to the bottom of the cabinet, but the greater complication relates to cabling.

Cable Entry

A panel used in an application of any complexity will have numerous cables and/or a busway requiring access.

- Busways are often used as power entries to link the cabinet with the transformer

- Power cables carry the main supply or power to motors and other pieces of equipment, and

- Control and command cables, along with communication cables with multiple conductors for data networking, (Ethernet, fieldbus, etc.), extend to sensors and other minimum power devices.

Cable entry points for an enclosure must be designed very carefully, as an incorrect cable gland selection or improper installation degrades the IP rating for the whole panel. Keep in mind that the ultimate rating for a panel is only as good as its worst connection point.

If you have an upcoming project that requires a custom panel, we can help you win! Kele’s Custom Panel Shop can save you time and labor.