I started at Kele about 19 years ago. Over the years I’ve been fortunate to learn a good bit about controls from many very talented folks – mentors, fellow employees, industry experts, and customers. It is easy to have favorites in my line of work. Being in tech support over an extended period of time, I have a base of products that I lean on. Usually it’s because a product is dependable, easy to use, and most importantly – it makes my customers happy. One of those products is the Honeywell T775 series of standalone controllers.

There are many times where a full blown building automation controller is overkill and simple control devices, like thermostats, don’t give the flexibility to offer the desired level of control. We get this call almost daily in the tech support pool. While there are several standalone controllers out there to choose from they can be cumbersome for some “small” jobs. Having to add on multiple modules to a basic controller adds complexity and cost. That is where the Honeywell T775 shines. This simple, cost effective controller can tackle many different control applications with one simple device. Easy to use, saves time, saves money, it’s easy to see why the T775 is one of the favorites of the tech support group.

Here are some of the features the T775 lineup has to offer:

- Easy to use graphical interface – it really is as easy as some smart phone applications

- 14 different models to choose from – Boiler control, reset, temperature, and universal models

- Optional NEMA 4X enclosures – for outdoor applications

- Setback models with internal time clock – maximize energy savings with unoccupied control

- Optional independent modulating output models – one controller for more than one task

- Optional modulating high or low limit controls – protect expensive equipment

- Reset models with simplified setup – changing control points based on environmental factors made easy

One of the most popular uses for the T775 is for controlling variable frequency drives in differential pressure applications, for both water and air. The simplicity of setup makes it ideal for these applications.

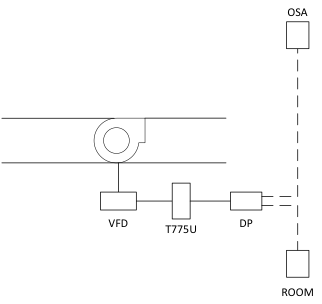

EXAMPLE: a VFD being used to control pressure in a building.

Parts List:

1) T775U Honeywell controller

1) Differential pressure transmitter (Kele DPA series, DPL series, Setra M264 series)

1) Room pressure sensor (Kele RPS, A-308-K)

1) Outdoor air pressure sensor (A-306-K)

Length of tubing (T-101, actual length determined by install)

The room pressure sensor (indoor sensor) and the outdoor air pressure sensor are piped accordingly to the high and low ports of the differential pressure transducer. The orientation of these sensors is determined by whether positive or negative building pressure is desired. If positive building pressure is required, pipe the indoor air sensor to the high port of the differential pressure transmitter and the outdoor pressure sensor to the low port. If negative building pressure is required pipe the outdoor pressure sensor to the high port of the differential pressure transmitter and the indoor pressure sensor to the low port. The differential pressure transmitter senses differential pressure and outputs an analog signal that is used as the input (process variable) to the T775 controller. The T775 modulates its output to control the speed of the fan based on the set point established in the controller setup.

The ease of setup combined with the adjustability of the T775 makes this application easy. The T775 uses an easy-to-read display and the setup is menu driven. The graphical interface actually walks the user through the setup, which saves valuable time and money on the installation. Pinpoint control with adjustable integral and derivative times is easy to achieve with the T775. And that’s not just for this application, there are many others. So the next time you have a “small” control job give Kele a call to discuss using the T775 and save yourself some time and money.

The meaning of the following is not clear –

Easy to use graphical interface – its relay is as easy as some smart phone applications

Hi Jean! That was a typo that has been fixed. It should read –

Easy to use graphical interface – it really is as easy as some smart phone applications.

Thanks for the heads up!!

I have a T775 controlling 3 domestic hot water boilers. How could I add a control to have them run with equal time.

Jim, thank you for your question. Unfortunately there is no provision within the T775 to do any sort of lead/lag or equal run time sequence. We do not offer such a controller but they are out there. Thanks

Can I use a T775 to hold 15 psi using a modulating valve. Possible a three way valve?

Good afternoon Mike!

Yes, you can use a T775 along with the T775U2006 and an appropriate pressure transmitter for the input. Our P51 series pressure transmitter would be a fine choice.

Thank you!